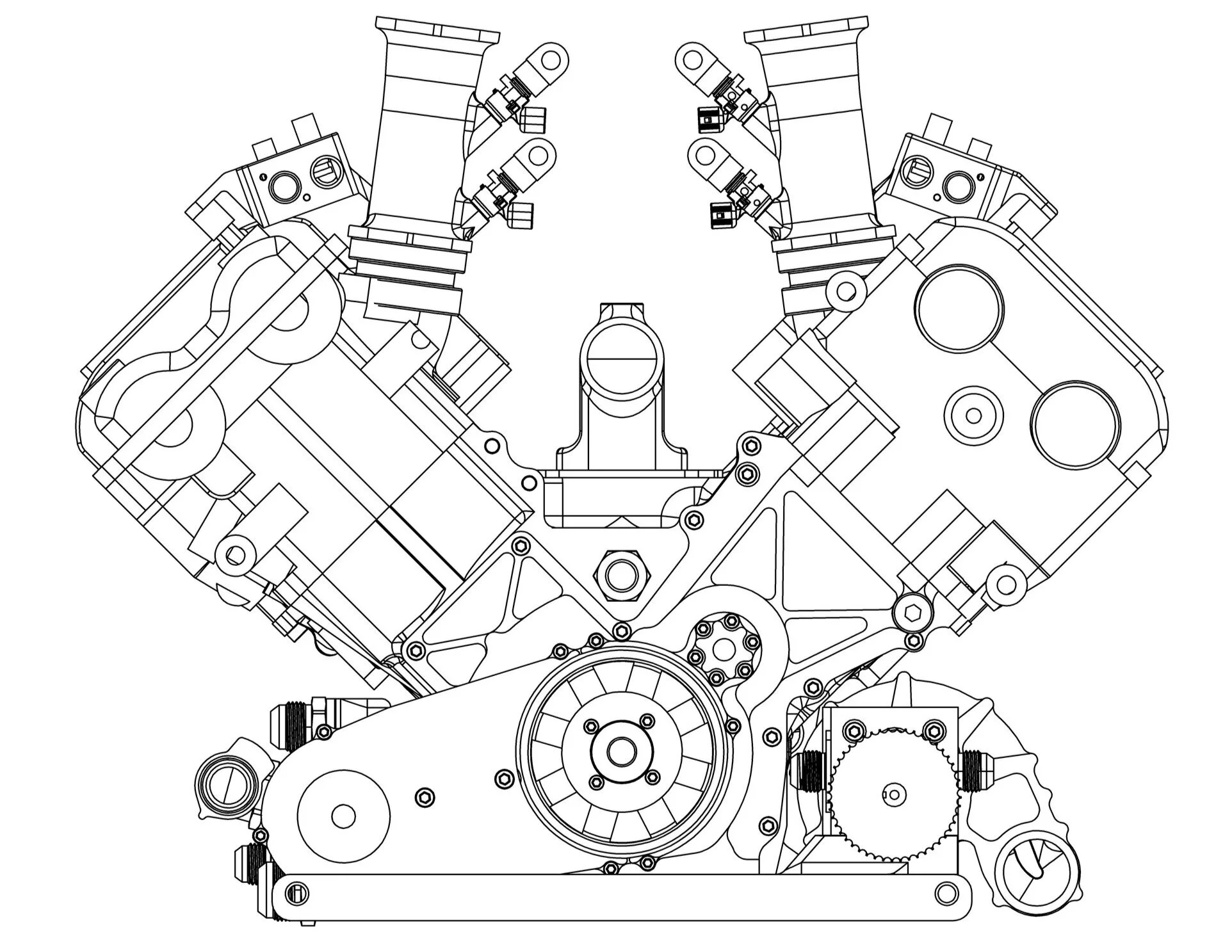

JFC-V8

Developed. Proven. Ready.

Since 2016 the Monobloc JFC V8 has gone through many stages of development. From what began with a naturally-aspirated 3.0L which yielded impressive power density, we wanted to push it further. In 2018 we began development of the world’s first Twin Turbo Hayabusa V8. The billet 2.8L package yielded even greater possibilities while still maintaining efficient packaging. We are continually developing and testing the limits of both packages.

3.0l NA V8

200lb Long Block

90 degree V8, flat-plane crank

84mm Bore x 68mm Stroke

4 Bolt Main ARP Studs

10,500 peak rpm

460hp and 280ft/lbs (current development)

5 stage Dailey Engineering Pump

Cylinder head and Camshaft options available for different build requirements

CP-Carrillo pistons 13.5:1

CP-Carrillo custom rods designed for 700hp

90mm crank centerline for lower chassis mounting

2.8L Twin Turbo V8

300lbs with JFC induction, headers, and EFR turbos

90 degree V8, flat-plane crank

81mm Bore x 68mm Stroke

4 Bolt Main ARP Studs

10,500 peak rpm

785hp and 505ft/lbs (current development at 16psi)

Two Dailey Engineering Pumps

Cylinder head and Camshaft options available for different build requirements

CP-Carrillo turbo pistons 9.5:1

CP-Carrillo custom rods designed for 1000hp

90mm crank centerline for lower chassis mounting

Lehmann style dual plenum induction, previsions for 16 injectors and Bosch DBW throttles

Inquire today to customize your JFC V8

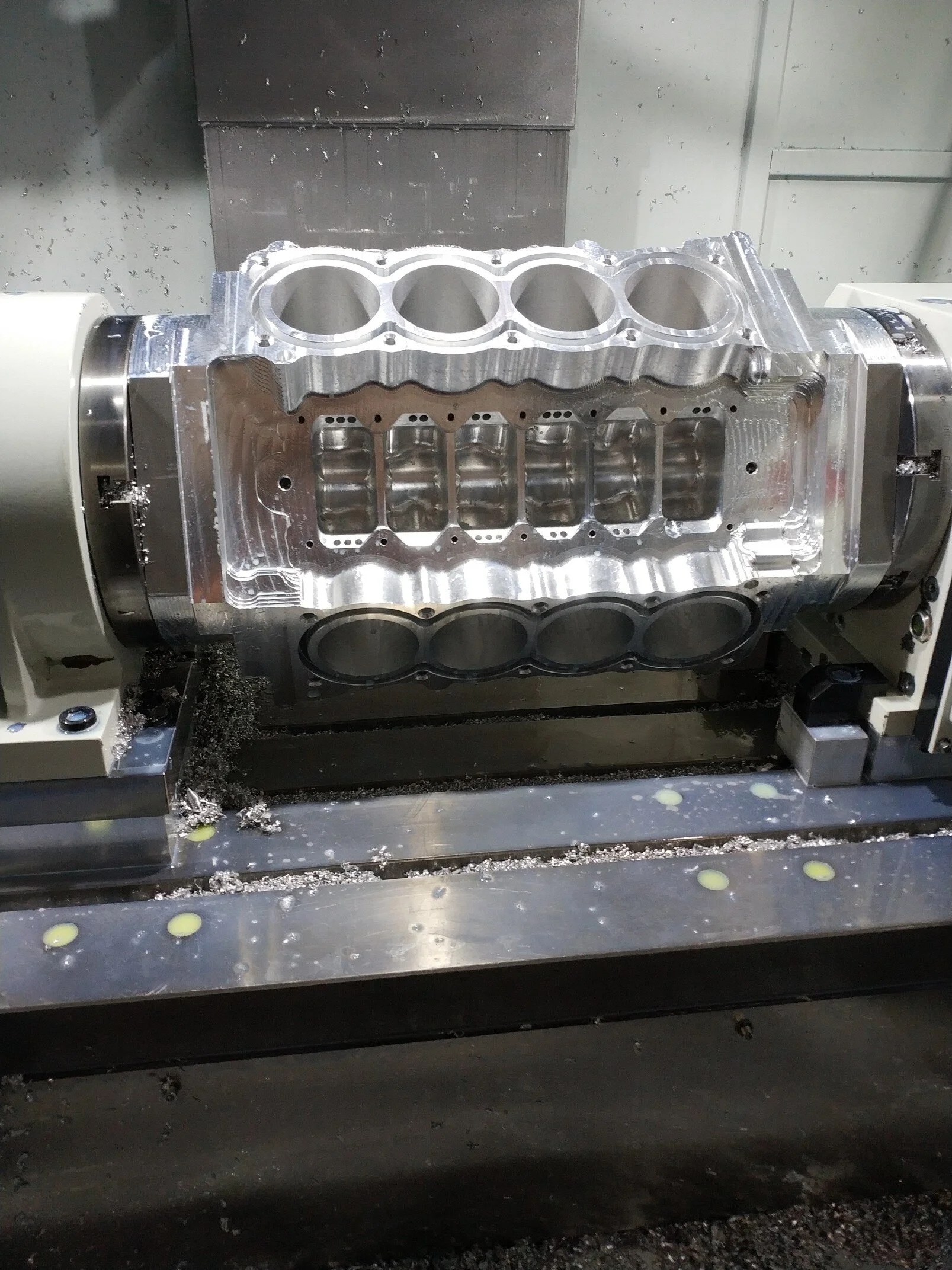

Manufacturing

All components machined in house from 6061-T6

Monobloc billet starts at 280lbs and finishes at 37lbs after 40 hours of machining time

Multiple rounds of quality control

Nikasil Plated by Millennium Technologies

Final assembly and blue printing in house

Custom adaptation available for any gearbox application